“This is a material with enormous potential, and we see great opportunities to produce netting and ropes with unique properties through this collaboration,” says Hans Petter Selstad, CEO of Selstad.

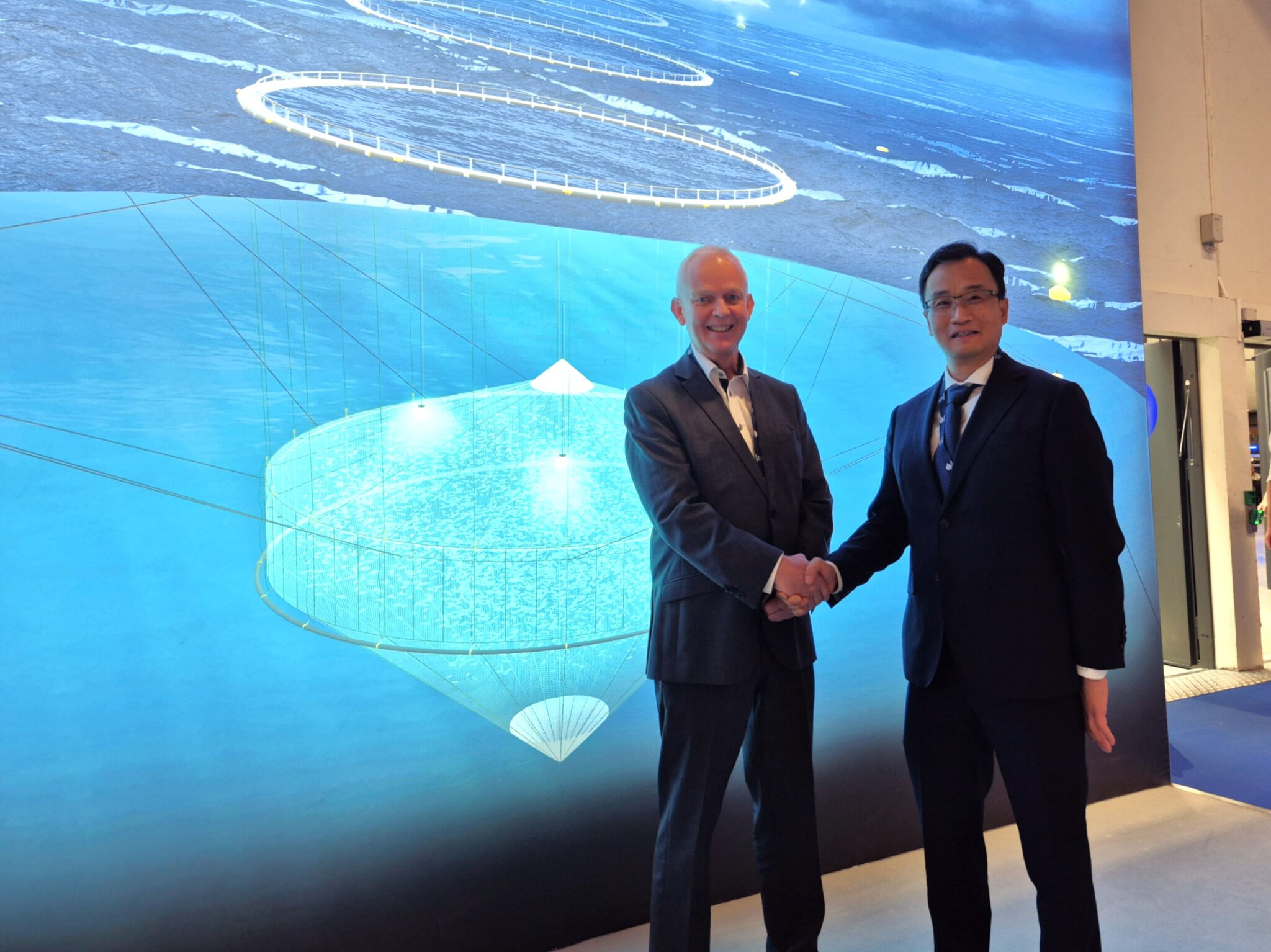

At Aqua Nor, Selstad and the Chinese company Baotou Zhongyuan New Materials Co. Ltd.signed the cooperation agreement, which means that Selstad will gain exclusive access to the Sundless material to produce, among other things, netting and ropes at their own rope factory in Måløy.

“We have already produced both netting and ropes from this material, and with these components, we have now also completed the first net bag for use in Norway,” says Hans Petter Selstad.

Significant gain throughout the lifecycle

Selstad’s R&D department has carried out extensive testing of the material from their new partner.

“We have tested raw materials from existing and potential suppliers for many years, and this one really looks promising,” explains Knut-Steffen Solvåg, Head of R&D, and elaborates:

“It has a capacity, abrasion resistance, and weight that make it very well-suited for producing ropes and netting. The combination of the strength of UHMWPE netting, extreme abrasion resistance and cut resistance makes this material completely unique. In addition, it is recyclable, and it is the only UHMWPE material that can be produced without the use of solvents. That means the environmental benefits of choosing equipment made from this material are significant throughout its entire life cycle.”

Involved in the entire process

CTO Steinar Hansen at Selstad has played a central role in the production of the first net bag—from processing raw material in China to final completion in Norway. After more than four decades in the aquaculture industry, Hansen believes Selstad has now taken a major step toward developing an optimal netting that meets fish farmers’ combined needs.

“We have had good alternatives to nylon nets for a long time. But the challenge with choosing stronger netting made from new materials has often been that the nets become very heavy and bulky, and costly for fish farmers to handle. Here we have a significantly lighter material, which will bring obvious benefits in many areas,” says Hansen.

He emphasizes that the product is still in the development phase and that Selstad is now dedicating additional resources to following up on deliveries in both the production and operational phases.

“We are in dialogue with several of our customers and hope to be able to put a significant number of net bags into the sea over the next year. Our industry has always been good at seizing opportunities to improve operations, profitability, and environmental impact. Here, we have found another such opportunity,” concludes Steinar Hansen.

siri.solbakken@selstad.no

+47 977 53 065